A company that could revolutionize the solar industry, with manufacturing based in Genesee County, is making progress on bringing its solar wafer technology to market at scale.

This week, 1366 Technologies announced that a Japanese energy company has opened a new power station using wafers manufactured with its proprietary high-performance wafers.

Though work is proceeding to prepare the STAMP industrial park in Alabama for its first tenant, there is no word yet on when there will be a groundbreaking for STAMP or for the 1366 plant, which could eventually employ as many as 1,000 people. The plant is expected to manufacture solar wafers primarily for export to industrial solar installations, such as the new facility in Japan.

Press release:

Silicon wafer manufacturer 1366 Technologies today announced that Japan’s IHI Corporation, through its wholly owned subsidiary IHI Plant Construction Co. Ltd (IPC), has completed the grid connection and begun commercial operation of a 500-kW solar installation featuring 1366’s high-performance wafers. During its lifespan, the array is expected to displace approximately 9,500 metric tons of CO2 from entering the atmosphere. 1366 and IHI celebrated the completion of the system this week at a ceremony in Tokyo.

“This commercial installation delivers all of the expected benefits specific to solar power and then some, the energy payback of an installation featuring Direct Wafer products is accelerated to less than a year due to the fact that our technology uses just one-third the energy,” said Frank van Mierlo, CEO, 1366 Technologies. “IHI has a long history of identifying and adopting groundbreaking technologies, we’re proud the Direct Wafer process is part of that story.”

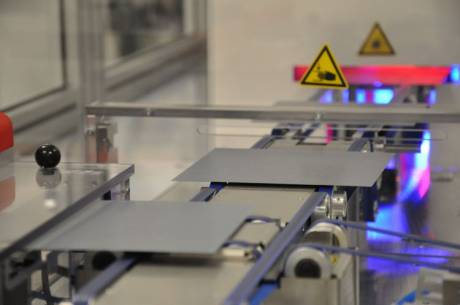

The array, located in the Japanese prefecture Hyōgo and consisting of IEC-certified modules fabricated by a Tier 1 manufacturer in China, includes more than 120,000 wafers made with 1366’s revolutionary Direct Wafer® process. All the wafers were produced at 1366’s demonstration facility, using the Company’s production-ready Direct Wafer furnaces.

This installation builds on the success at test sites in the United States, Germany and Japan and demonstrates the Company’s ability to run the Direct Wafer process at scale. It also underscores the broad appeal of the technology downstream where customers want advanced, high-quality systems with lower carbon footprints.

“It has been our goal to expand our portfolio of renewable energy systems with innovative technologies that dramatically reduce cost and deliver superior performance of photovoltaic systems. This installation achieves that goal,” said Otani, of IHI Corporation.