It's a place teeming with wildlife, a bit of a birder's paradise. It's 400 acres of accessible open space where local residents can walk their dogs, go for a jog or just enjoy a stroll along well-maintained paths.

Some might call it a park.

We call it the Batavia Wastewater Treatment Plant.

A lot of area residents, even if they know of the plant, may not know it's open to the public, or appreciate its natural aesthetics.

"It's great that the city is able to provide access to this great resource," said Tom O'Donnell, president of the Buffalo Ornithological Society. "It's a unique place to view waterfowl and shore birds."

Some 180 different species of birds have been spotted on the property during its 21-year history, including herons, loons, egrets, hawks, terns, swans and, of course, a variety of ducks and geese.

Birders from throughout the region know of the facility and have even traveled from as far away as Finland specifically to go birding in Batavia.

What makes the plant unique is the lack of reeds and trees between the birder and the birds, said O'Donnell. The vantage point, with the raised berms around the lagoons, give birders an exceptional angle to view waterfowl and shore birds.

It's tempting to call the fenced-in treatment plant a bird sanctuary, but it's prime function is to treat the city's effluent and turn it into something environmentally safe to pump back into the Tonawanda Creek.

The process is all natural -- no chemicals -- and it takes six to nine months for a molecule of water to pass from the facility's mechanical screen to the gravity outflow pipe near the pedestrian bridge at Walnut Street on the Tonawanda.

According to City Manager Jason Molino, the treatment plant is the largest lagoon system east of the Mississippi.

"That plant is a resource that I don’t think people understand," Molino said following a city council meeting last week. "It’s a special plant. It’s 400 acres. It doesn’t use chemical treatment. It’s natural treatment, so there’s no chemical cost. Only four people run it, seven days a week. You find me a sewer plant that has low labor costs like that, low treatment costs -- that's why our sewer rates are some of the lowest in Western New York."

And the plant is paid for. A combination of federal grants and municipal bonds helped get the plant constructed and the bonds are all paid off.

It even generates a little revenue (besides sewer-rate fees). A contractor pays up to $6,000 a year to harvest fat head minnows from some of the ponds. The minnows were brought in to help balance the treatment of the water, and while birds feast on the little fish, they breed faster than even the hungriest herons can consume them.

The plant's natural treatment process is not without precedent, according to Rick Volk, chief operator of the wastewater plant.

"The idea of lagoon treatment is as old as Egypt," Volk said. "What we did in Batavia is take a system that is as old as Egypt and apply new technology."

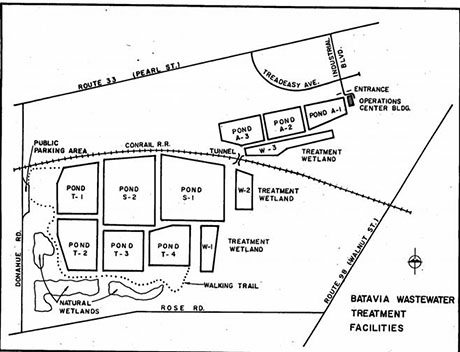

From 2.5 to 3.5 million gallons of raw sewage arrives at the plant daily (capacity is 5 million gallons per day). It is pumped into a screening process that removes everything larger than a cigarette butt, then goes through an aerated grit chamber to remove sand and dirt (this is the one part of the plant that produces any real stench).

After screening, the effluent is pumped into aerated ponds. The ponds provide oxygen treatment that consumes matter in the wastewater. Air is pumped into the water by 200 horsepower compressors. This process takes about a month.

The aerated ponds are popular with ducks who can be found by the dozens either in the water or resting on the long, black aeration pipes that float on the surface of the water.

The wastewater is then fed alum to assist in phosphorus removal as it flows into two secondary ponds. The 45-acre ponds are up to 8-feet deep where biological activity and settling removes more waste. The process takes up to 42 days.

Next, a lift station hoists the water up above the four tertiary ponds, which are from 25 to 35 acres each and have an adjustable depth of 3 to 12 feet. At this point, most of the suspended solids are removed.

This is where you'll find minnows and the waterfowl who feed on them, as well as a variety of other birds flitting through the air, from northern flickers to least flycatchers.

The final step on a molecule of water's journey is to pass through one of three wetlands -- ponds with reeds and other aquatic plants that help "put the final polish," as Volk said, on the wastewater.

The largest of the ponds is popular with ducks, geese, herons and snowy egrets.

The whole process is designed to ensure that only water that is safe for people, crops, fowl and fish is piped back into the Tonawanda.

Plant staff conduct frequent tests -- regulated by the state -- in a lab at the facility to ensure each step of the process is cleaning the waste as it should and that the final product shipped out to the Tonawanda is up to environmental standards.

Staff is on duty from 7 a.m. to 3 p.m., which is the only time the ponds are accessible to the public.

The current four staff members are about half of what the city needed to run its pre-1990s wastewater plant, according to Volk.

While not officially a park, as long as the plant is open, area residents are welcome to visit anytime during plant hours, Volk said.

Guests are asked to sign a registry in the main building, but are then free to wander the property. With permission, guests can drive their cars -- it can be a long, long walk to the tertiary ponds -- on the well-maintained gravel roads that surround the ponds.

Volk said there are times when work being performed by staff will prevent guests from driving on the roads, which is why it is necessary to ask first.

And if you go, you really want to get back to either the tertiary ponds or the larger of the three wetlands. This is where you will see the greatest variety of birds.

There's also a park of sorts on the west end of the facility, along Donahue Road. There's a small parking lot and footpaths that allow, at points, for visitors to view the tertiary ponds as well as a reconstructed wetland -- abatement for a wetland destroyed when the plant was built. The area is open to the public at all times, but no hunting or trapping is allowed.

More reading: The Wiki Guide to Birds.

If you have trouble viewing the slide show below, click here.