A high-ranking official of the local industrial development agency that owns the Western New York Science and Technology Advanced Manufacturing Park says Plug Power’s investment in the Town of Alabama site will more than offset the loss in revenue caused by removing about 1,100 acres of mostly farmland from the tax rolls.

That official, Mark Masse, is senior vice president of operations for the Genesee County Economic Development Center.

“I know that people get upset with farmland coming out of production but when you have projects like Plug Power that can give you a 10 to 25 times rate of return, that is a significant help – not only to the agricultural community but also your residents,” Masse said.

“We do not give money away. We do not give out bags of cash. That is what everybody seems to have a misconception about. We give an abatement, so they don’t pay the tax.”

Masse and Jim Krencik, the agency’s director of marketing and communications, sat down with The Batavian earlier this week at their Upstate Med & Tech Park office on R. Stephen Hawley Drive to talk about STAMP and the GCEDC’s other ventures.

According to Masse, the agency has acquired 25 parcels equating to 1,144 acres of STAMP’s total of 1,250 acres. He said the assessed value of those properties is about $3 million.

He said that based on 2020 tax rates, that comes to about $104,00 a year for all three taxing jurisdictions – the Town of Alabama, Oakfield-Alabama Central School and Genesee County.

“So, if you were to say that we owned all of those properties for the 10 years – which we didn’t, because we acquired them over time – so you couldn’t apply 10 years to all of them,” he said. “But if you did, that would just be about a million dollars in tax revenue lost over 10 years.”

‘A SIGNIFICANTLY BIGGER PAYBACK’

Masse said that pales in comparison to what Plug Power, the Latham-based producer of green hydrogen fuel cells, will be paying to those three entities as a result of agreeing to build a $232.7 million manufacturing plant and $53 million, 345/115 kilovolt electric power substation at STAMP.

“The Plug Power project will generate a significantly bigger payback than all of those combined,” he said. “So, that’s the big windfall, so to speak, for these municipalities. These are 20-year agreements we’re entering into for Plug Power and those payments are about $1.4 million a year to the taxing jurisdictions, compared to previously collecting only $104,000.”

The contract with Plug Power includes a PILOT (payment in lieu of taxes), community benefit agreement and community education agreement. Masse said those are classified together as a property tax and it is "additional revenue for the taxing jurisdictions being driven by the project.”

Directors of the GCEDC have approved $118.8 million in property tax ($117.7 million) and sales tax ($1.1 million) abatements for Plug Power.

Krencik said the incentives are based on Plug Power’s performance outlook, including a pledge to create 68 full-time jobs, with salaries and benefits equaling about $70,000 per job.

“When considering the company’s capital investment, job creation, initial investment and projected revenues, the estimate economic impact is $4.40 for every $1 of requested public investment,” he said. “Comparing that against all of our corporate taxpayers in Genesee County, aside from utilities (National Grid, National Fuel), when you look at a single-source business, such as a theme park or a manufacturer, this would make this project the largest single company taxpayer of all those in Genesee County.”

“Unlike when the land – mostly farmland -- was vacant and you had $104,000 in annual taxes, this $1.4 million that Plug Power is going to pay is on 30 acres,” Masse added. “So, that’s a significant rate of return that you see on these types of projects.”

KRENCIK: FOLLOWING THE MODEL

Plug Power is the first tenant at STAMP, which has sat dormant for many years. In 2016, Gov. Andrew Cuomo came to Batavia to announce that 1366 Technologies, a solar wafer manufacturer based in Massachusetts, would be building a facility at STAMP but that deal eventually fell through.

Krencik said the GCEDC was following a model used by other municipalities – acquiring land and working to install necessary infrastructure to attract interest from mega-companies such as Plug Power.

He said he understands how inactivity at these large sites could lead to public dissatisfaction, while the lack of progress isn’t as evident at smaller manufacturing parks, such as the Genesee Valley Agri-Business Park on East Main Street Road.

“That’s kind of been the model across all the towns – you typically see a shorter timeline on some of these things because they’re smaller projects, smaller sites, smaller infrastructure,” he explained. “In the case of an ag park, I don’t think you’d feel the same type of pressure where you may be thinking, ‘Is there a loss there?’

“There are acres in the ag parks that currently are not on the tax rolls, but, of course, you already see the benefit in Batavia where you have two very large operations that are significant contributors to the town, city schools and the county (HP Hood and Upstate Milk Cooperative).”

Masse agreed, adding that the GCEDC is running out of acreage, “but that’s a good problem to have.”

MASSE: FARMERS BEAR THE BURDEN

Getting back to STAMP, Masse said the GCEDC continues to pay the fire district fees on those properties as they are not tax exempt.

“So, the emergency fire support services are still being paid for all the properties that we own, with the tax based on the assessed values and fire district tax rate,” he said.

Masse also mentioned that many parcels zoned Agricultural receive property tax exemptions.

“Obviously, agriculture is the No. 1 industry in Genesee County and if you look at who bears the largest tax burden in the county it is farmers, because they own the majority of the land,” he said. “That’s why they try to give them some help with the ag exemption. They’ll scale them in over a time period.”

He brought up a municipal consumption study that was done in Amherst around a decade ago that showed that commercial enterprises consume about 80 cents in municipal services while residential consumes around $1.20 in municipal services.

“Everybody complains about these companies but, in the long run, they’re going to help subsidize the municipal services that the residents use more of,” he said. “That’s always our hope that we’re not only creating jobs but also creating additional tax base to alleviate the tax burden. Creating those jobs and having those people spend their money here … what they call the indirect and induced effect of that money being spent throughout your community.”

COMPANIES MUST MEET THEIR GOALS

Masse said companies’ economic impact projections are keys to determining if they qualify for tax incentives and the amount of those incentives.

“Firms are required in their applications to give us the number of full-time equivalent (jobs) that they believe will be created by their projects,” he said. “Back in October of 2015 or 2016, the law changed. Now, that job creation goal is put into our PILOT agreements and other agreements. If they do not achieve that, our board could consider cancelling their PILOT and making them claw back and basically, pay back the incentives that they took.”

He said the GCEDC tracks companies as long as they are receiving benefits and that the board of directors would likely would call in a company to find out why it didn’t reach its goals.

“So, for the 10 years of a PILOT, they are required to report to us their annual job numbers every year. We record them and input them into the New York State reporting system – PARIS (Public Authorities Reporting Information System),” he said. “It’s a public document that shows how many jobs were pledged and how many were created. Once the PILOT expires, the company is no longer required to report those jobs to us.”

Krencik credited Masse for staying in touch with the cities, towns and villages that usually initiate construction projects.

“Mark meets with the town, the school and the county folks more than I meet with members of my immediately family,” Krencik said. “He has kept that dialogue going. At the town board level, for example, that is a strong mode of communication.”

STAMP DIVIDED INTO ‘DISTRICTS’

A look at the layout of STAMP reveals that it is divided into three “technology districts”:

- Technology District 1 -- a 600-acre parcel in the northern portion dedicated to high-tech manufacturing, including semiconductor, renewable energy and other advanced industries;

- Technology District 2 -- office, and research and development space;

- Technology District 3- -- area geared toward retail support services.

Masse said the concept was to create blocks of three semiconductor chip “fabs” that would open six million square feet for production, accommodating 930 employees.

“We went through the required State Environmental Quality Review, with the full build-out (as such) that if it’s within those thresholds, we really don’t have to do more work,” he said. “When we proposed to rezone the property, that is an action under SEQR and any proposed changes have to comply with SEQR.”

He said that’s what the GCEDC did in 2010 and “that took the better part of two years to get through that process.”

POWER, GAS LINES ARE RIGHT THERE

Masse also said that the presence of the nearby dual 345kV power lines and a National Fuel Empire Pipeline, a 24-inch natural gas transmission line, was a major reason the Town of Alabama location was selected.

“The 345 kV power lines take power from the Niagara Falls power station and run it down to New York City. We did a system impact study that revealed we can pull down 450 megawatts off of those lines,” he said. “With that, we would construct a very large, about a 10-acre substation (on the site), that would be a 345 to 115 kV – it would step the voltage down.”

As previously stated, Plug Power is funding this substation at a cost of about $53 million. Both the Plug Power plant and the substation are expected to be operational by December 2022.

Plug Power, along with the 30 acres it purchased for the green hydrogen facility, has a right of first refusal for an adjoining 30 acres for the possibility of future expansion.

The GCEDC has no applications for other major manufacturers at this time, Masse said. A couple months ago, it was rumored that Samsung was interested in placing a semiconductor manufacturing plant at STAMP.

INCREASED INTEREST IN STAMP?

When asked if Plug Power’s pending move to STAMP has generated more interest in the site, Masse said he’s hopeful that other businesses will take note. He did, however, mention that the COVID-19 pandemic “has driven a lot of companies to take a hard look at where they’re sourcing their products from and where are they selling their products to.”

“COVID broke a lot of supply chain issues throughout the world,” he said. “I think we’ve seen that with shortages and price increases of a lot of things. A lot of companies are doing a reassessment, saying we don’t ever want to go through that again.”

As a result, Masse said that companies are looking to locate new facilities coming out of COVID-19.

“So, one of the nice things about the Plug Project is that timelines are crucial to these companies – time is money to them,” he offered. “That substation is a major piece of infrastructure. Having that in place will go a long way toward alleviating companies’ concerns about that being available. We have the force main of the sewer project under construction. The only real long lead time item left will be the water from Niagara County, and we are just completing our design and engineering on that as well.”

Masse said he sees a light at the end of the tunnel.

“A lot of people say, well, it’s been 10 years and all you have done is build a road. They don’t see the amount of soft work, so to speak, that is in my office in about 2,000 pages worth of documents of archaeological, environmental, phase one, phase two – all the design and engineering you have to do and all the regulatory agencies you have deal with. That takes time, and that’s what we have been working on very diligently,” he said.

The development of STAMP has been beneficial to Town of Alabama residents already, he said, in that they gained access to municipal water.

“If we had not done this, they could not afford to get municipal water,” he said. “They had failing wells. A lot of those people were spending $1,500, $2,000 a year on replacing equipment because the water was so bad. And because we were able to fund a significant portion of the water, the town was able to add on and they’re going to end up covering about 95 percent of town residents with public water.”

CORPORATE PARKS IN FULL SWING

The GCEDC has invested tens of millions of dollars in the STAMP project, likely more than anticipated, but Masse said he is confident that the agency’s track record of success in Genesee County will produce a similar outcome in the Town of Alabama.

“If you look at our corporate parks, they’re almost all full at this time,” he said. “It was 2007 when the Ag Park was started. You can see the success that we have had there.”

The Genesee Valley Agri-Business Park is one of seven corporate parks owned by the GCEDC. Currently, HP Hood, Upstate Niagara and O-At-Ka Milk Products are running at high capacity and are expanding, Masse said.

The other corporate parks are as follows:

- Le Roy Food & Tech Park in the Town of Le Roy: BioWorks has just signed to take 60 of the park’s 75 acres, and the Le Roy Town Board has set a public hearing for July 8 to consider rezoning neighboring parcels for expansion.

Word has it that Great Lakes Cheese, an Ohio-based manufacturer, has approached individual landowners with purchase offers. Masse said Great Lakes Cheese has yet to apply to the GCEDC for incentives.

“We do not have any applications from any companies for that location,” he said. “A lot of companies will go out and do due diligence on sites. We do not own the property. Whoever is talking with private landowners is between them.”

- Apple Tree Acres, Bergen: Sixty-two percent of the acreage there is sold, with Liberty Pumps as the key tenant. Liberty Pumps is undergoing an expansion project as well.

- Gateway I and Gateway II Corporate Park, on both sides of Route 98 near the Thruway exit: “All of those acres are spoken for,” Masse said.

- Med Tech Center on R. Stephen Hawley Drive: The GCEDC has renovated 800 square feet of space in that building that is available for lease.

- Buffalo East Tech Park in Pembroke: Artisan cheese maker Yancey’s Fancy has a new plant there and a couple smaller businesses are being proposed for that site.

Masse said he believes that the more the public knows about economic development projects, the perception that the GCEDC is just an administrator of corporate welfare will subside.

“We’ve tried to do public outreach sessions, but they were poorly attended,” he said. “However, all of our agency business is open to public viewing. From a transparency standpoint, we are as transparent an organization as you’re going to find. Everything is on our website. Our board meetings are recorded and they’re Zoomed. Everything we have is out there under public authorities law.”

----------------

SENECA NATION FILES SUIT

In a separate development, Masse said it is agency policy to not comment on any pending litigation.

Earlier this month, the Tonawanda Seneca Nation filed a lawsuit in state Supreme Court in Genesee County, disputing the GCEDC’s determination that the Plug Power project would have no negative effect on the nation’s “Big Woods” land that is situated on the western end of STAMP.

According to the lawsuit’s preliminary statement, the Seneca Nation considers that area “as a property of religious and cultural significance” and that the Plug Power siting would infringe upon those grounds. The plaintiff also contends that the GCEDC did not provide notification prior to the completion of the environmental review process.

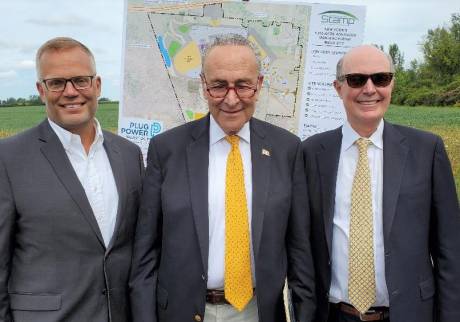

Photo at top: Mark Masse, right, and Jim Krencik at the Genesee County Economic Development Center on R. Stephen Hawley Drive; Photo at bottom: A look at the WNY STAMP site, with the Plug Power project area "X'd out" just south of the Technology District 1 area highlighted in purple. Photos by Mike Pettinella.