There's more to 1366 Technologies slipping away from the STAMP project than just losing the first company to commit to the technology park in Alabama -- it's also a loss of the kind of innovative company that would be good for the region, said Genesee County Economic Development Center CEO Steve Hyde during a meeting today with local reporters.

"These guys really do have a very innovative product," Hyde said. "They're changing an industry that's a high-growth industry. Usually, when you have credible quality IP (intellectual property) married to an industry of high growth, the sky's the limit. That was something that I really loved because we would be really introducing that kind of innovation here in our community, which has always been part of what I've been trying to cultivate in our community."

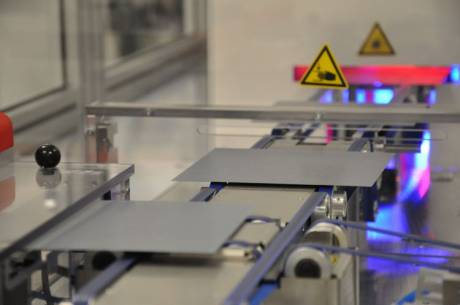

As reported earlier, 1366, which makes silicon wafers for solar power, announced today that they would not build their first full-scale production facility in Genesee County after the company and the Department of Energy were unable to agree on terms for a loan guarantee.

Already with more than $80 million in the bank from private investors and tax abatements guaranteed by GCEDC and Empire State Development, 1366 was trying to finalize a $150 million loan guarantee to help get its plant, with 1,000 local jobs, up and running. The original DOE guarantee was granted in 2011 but 1366 still needed to raise $100 million in private equity both to unlock the funds and to finance the first phase of the plant construction. (The public support for the project totaled $56.3 million in tax abatements and state grants over 10 years. Since 1366 never finalized financing and closed on the transaction with GCEDC, the company received no taxpayer money.)

Laureen Sanderson, a spokesperson for 1366, said the DOE agreed last year to reopen discussions on the loan guarantee but when it came time to renegotiate the agreement, it was clear there would be no guarantee the funds would be available at the end of what she said would be an expensive and lengthy negotiation process.

Earlier today, Rep. Chris Collins issued a statement blaming the breakdown in the funding process on 1366, saying it was evidence that the company was never serious about building its plant in the United States.

"Despite being approved over six-and-a-half- years ago and my office facilitating multiple contacts between 1366 and the Department of Energy, the company failed to complete the necessary requirements of their contract and has had to terminate its federal loan offer," Collins said in a statement.

According to 1366, it was their decision to withdraw its application, not the DOE terminating the agreement.

A statement from the Department of Energy supports that position.

1366 Technologies has withdrawn from its Loan Guarantee Agreement that was signed with the Department of Energy (DOE) in September 2011. 1366 Technologies has shown the potential to introduce an innovative American manufacturing technology, which is why the Loan Programs Office issued the loan guarantee to support commercialization efforts, following up on previous DOE support for the company’s research and development.

According to sources in support of the congressman's statement, the DOE twice "renegotiated" its agreement with 1366. A source at DOE would only say that the DOE extended the date of its loan guarantee in response to discussions with 1366.

Sanderson chafed at the accusation by Collins that the company wasn't serious about building its first facility in New York.

She said the company completed environmental assessments, preliminary designs, permits, and worked diligently to line up economic support and financing for a local plant. That was a lot of time and expense to invest in the project, she said.

"The fact that our seriousness is being questioned is troubling," Sanderson said. "I don't know how many other ways to make it clear that our commitment was there."

In a story earlier today, The Batavian shared a report about a budget proposal from the Trump Administration that would slash funding for the very program 1366 would need for its loan guarantee.

Collins responded to that report with the following statement:

Anyone that will blame President Trump and his budget for 1366 pulling out of their contract with DOE is misinformed and completely unaware of how these types of arrangements actually work. To start, the funding for this project was approved six and a half years ago, so the President’s proposed FY19 budget would have no impact, not to mention that Congress, not the President, authorizes and funds these types of programs. After renegotiations that consumed DOE resources, 1366 was still unable meet the requirements agreed upon in their contract. To me, it seems like 1366 was spending the last six and a half years playing the field to see if they could get a better deal elsewhere.

Asked today if he was ever worried whether 1366 was seriously committed to STAMP, Hyde said there was never a hint that 1366 wasn't fully invested in opening its first plant in New York. He also knew, however, there was no guarantee until 1366 finalized its financing.

"I also realized and appreciated that there was still a startup company," Hyde said. "The challenge that a startup company has is the capitalization of their project. It is a major challenge that well-established companies with good balance sheets don't have to be concerned about. So, I'm a realist and I knew that that was always a risk and that's really what ended up happening here. The markets moved and the project changed."

The Batavian first spoke with Hyde about delays that could endanger the project in the fall of 2015, shortly after an expected groundbreaking at STAMP didn't take place.

Hyde said the delays had nothing to do with support from Empire State Development or the governor's office.

"The governor has been nothing but incredibly supportive," Hyde said. "I mean he I think he really believes that we can we can re-engineer the economy of upstate with high tech."

The big issue, from Hyde's perspective, is that the solar industry is growing and changing fast. That turbulence makes it hard for any startup to attract private investment.

It might seem there's a contradiction at play here. In the fall of 2015, groundbreaking on STAMP was delayed. Now, construction is underway, but not much regarding financing for 1366 changed between now and then.

"I have to beg to differ because there were things going on on the market side of the deal," Hyde said. "There were changing timelines for the project, the 1366 project, and what that does is it makes you decide to walk or jog while you do certain things relative to infrastructure versus run to support the project because then you optimize your cost profile as you do it."

Those changing market conditions played a role both in the fact 1366 didn't meet the requirement of the original DOE agreement to raise $100 million in equity and its requests for extensions of the agreement.

In November, besides the $100 million in private equity, the only other requirement a DOE source said 1366 was failing to meet was its obligation to select a site in the United States for its production facility.

The truth, was, however, that 1366 already had selected a location: STAMP in Alabama, in Genesee County, in New York, in the United States.

Hyde said the DOE's claim didn't make much sense.

"There was a signed state incentive proposal that talks specifically about where they were locating," Hyde said. "Then there was a signed local financial assistance application. This wasn't just a handshake deal. Governor Cuomo won't come and do a big announcement event like that if there isn't some serious negotiations and a documented commitment. Those documents have the signature of the CEO of 1366."

Sen. Charles Schumer has been supportive of both STAMP and 1366. The Batavian reached out to his office today to see if his staff might be able to offer insight into what went wrong with the project.

Spokesman Jason Kaplan issued the following statement:

It’s disappointing to learn that 1366 is withdrawing from pursuing this loan. Senator Schumer personally called DOE Secretary Rick Perry on Oct. 5, 2017 in support of 1366 and to request Secretary Perry meet with 1366 Technologies CEO to work with 1366 on a path forward. As a result of Senator Schumer’s intervention, Secretary Perry personally met with 1366 Technologies the following week on Oct. 11th. 1366 characterized the meeting as constructive and pivotal in finally allowing 1366 to open dialog with DOE and to map out a series of benchmarks the parties would work toward to move forward. We were hopeful they would move forward.

Jason Conwall, on behalf of Empire State Development, issued the following statement:

New York's commitment to 1366 Technologies was contingent upon their securing additional financing and since they have withdrawn from their DOE loan agreement, we won’t be able to move forward with the project at this time.

Today, Hyde said the loss of 1366 -- at least temporarily -- is not a setback for the project. In fact, just the fact that 1366 came along has helped move STAMP into a position to help it better appeal to site selectors for large high-tech companies looking for manufacturing locations.

"They did catalyze our ability to start the infrastructure development efforts at the site, which now makes the site far more competitive and attractive for another project to the scale of that one," Hyde said. "Now there's roadways in there. There's water lines and fire hydrants OK. New York State is committed to this. Howard Zemsky said we're going to keep going."

The withdrawal of 1366 also opens up a very attractive 100-acre parcel in the park.

"It's also protected by beautiful woods and wetlands," Hyde said. "You have a road in, it's blocked by woods, so when you pull in and then it's like, 'whoa.' It's a hundred acres that is just flat. That is something that many high tech companies find very attractive. There is a little bit of privacy, an environment where you can build a creative-class campus with walking trails, picnic areas, nature, respectful of the world conditions that we have. You got access to hydropower, sustainability. All of those things play very well into what high tech companies look for today."

There are at least four companies actively engaged in considering STAMP. There are have been two companies inquire about it that could take the entire park in one swoop. There's a company that could bring in 3,500 jobs within three years.

In planning for 1366, STAMP is positioned well to attract what Hyde called, metaphorically, the small house. The house that needs a smaller foundation. Those are not the companies currently most interested in STAMP.

"We now have the infrastructure to support a project of that (1366 Technologies) size and scale," Hyde said. "What we're seeing now, right now, today, with the four or so projects that are in our pipeline is projects that are much bigger than that. They need infrastructure much bigger than that. In other words, we need the funding to fund the blueprint for the big house. So the big water, the big sewer, the big electric, and that is the ongoing conversation that we're having with the state right now. This is not the time that we can pick up our toys and go home. This is time to double down and go harder because we're seeing deals that validated this site, and 1366 certainly validated it."

Hyde said ongoing negotiations with site selectors also validates the value of STAMP.

"We've got a project right now that has kicked the tires of this site and had five site visits," Hyde said. "They've had their engineering teams, their business teams, their marketing teams, their workforce teams in our place for like 14 days due diligence. Those companies wouldn't be spending that kind of time if this wasn't real.

Nothing is written in stone, though. STAMP is just one location among many these big companies can choose. Now that the infrastructure is in, it will be easier for GCEDC and ESD to move quickly but markets move fast -- as 1366 seems to prove -- so there's a lot that can go wrong on the road to new high-tech jobs.

"If this happened in Silicon Valley, it might not even hit your radar screen to make the news because high-tech projects come and go and morph and change," Hyde said. "In our world, it is a little different.

"This is new for us, so we need to continue to remember that we've got to put our battle gear on every day and continue swinging at this stuff because we have higher ed and the educational system assets. We have great infrastructure. You need to spend some more money to put that stuff together like we're doing with STAMP. But, you know what? We have real potential."